Mechanical conveyor systems for safe transport.

Precise, dust-tight and gentle on materials.

Specific conditions for production and demanding materials require a high level of throughput and accuracy. To convey these bulk materials to a specific point, we use trough chain conveyors as well as tube and trough screw conveyors below boiler and filter systems.

Use of mechanical conveying systems

- Transport of demanding bulk materials and dusts

- Horizontal and increasing conveying ways

- Closed system for a safe conveying

- Low wear and low maintenance

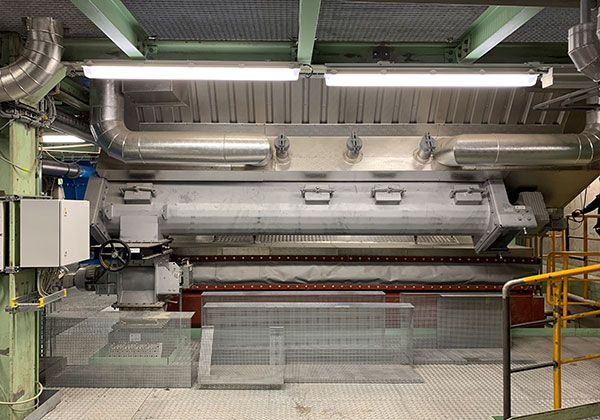

Trough chain conveyor

Closed conveying of bulk materials

For a safe and continuous flow of fine to coarse- grained materials and long conveying distances, chain conveyors are used, which transport the bulk materials horizontally or over inclines.

Your advantages

Low maintenance systems

High conveying volume

Conveying of fine-grained and coarse-grained bulk material

High temperatures of bulk material possible

Long conveying distances possible

Your contact for thin phase conveying

Contact person

Mr. Käuser

phone: +49 2734 509-34

email: thomas.kaeuser@f-a-t.de

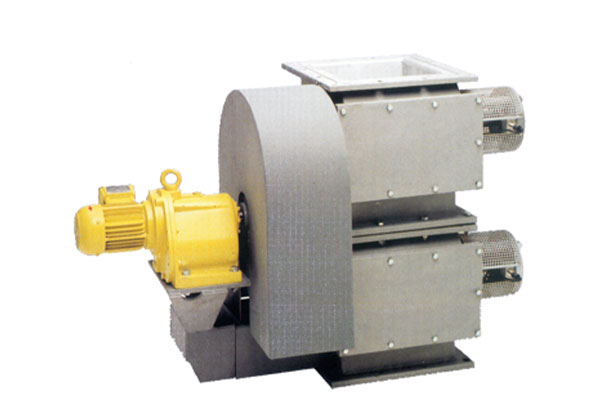

Pipe screw conveyor

Conveying fine-grained and coarse-grained bulk material

Pipe screw conveyors belong to the closed screw conveyor systems. The material is transported by pipe trough. Material temperatures up to 450°C are possible.

Your advantages

High conveying volume

Your contact for pipe screw conveyor

Contact person

Mr. Käuser

phone: +49 2734 509-34

email: thomas.kaeuser@f-a-t.de

Trough screw conveyors

Conveying fine- and coarse-grained bulk materials

Trough screw conveyors are closed screw conveyor systems for the transport or discharge of bulk materials. Material temperatures up to 450°C are possible.

Your advantages

Suitable for discharging from bunkers for dosing

Suitable for fine to coarse-grained trickling bulk materials

High conveying volume

Easy to maintain

Your contact for trough screw conveyors

Contact person

Mr. Käuser

phone: +49 2734 509-34

email: thomas.kaeuser@f-a-t.de

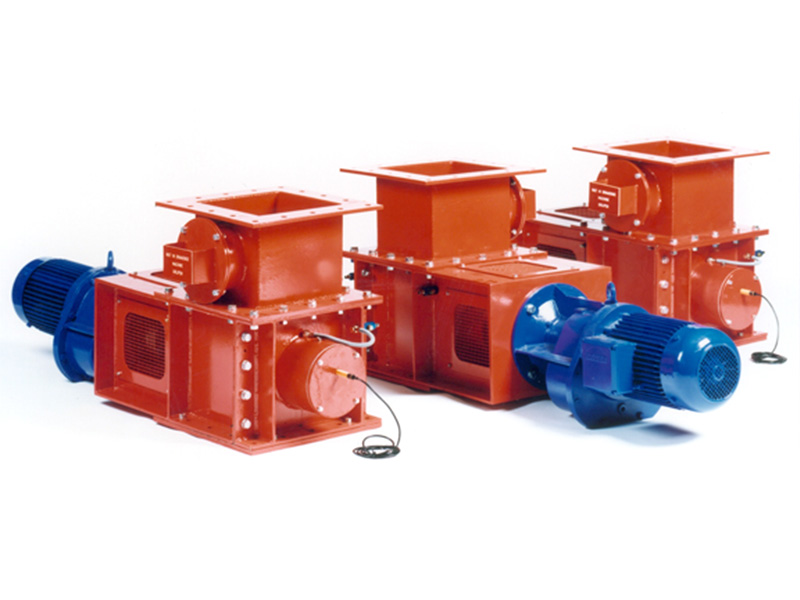

Rotary valves

The FAT rotary valve is used for the continuous discharge of dust bulk materials from silos and discharge hoppers.

Your advantages

High operational reliability

Easy maintenance

Good accessibility to the maintenance areas

Your contact for rotary valves

Contact person

Mr. Käuser

phone: +49 2734 509-34

email: thomas.kaeuser@f-a-t.de

Double pendulum flap

FAT-specific component

The double pendulum flap is motor-operated and is available in various sizes.

Your contact for double pendulum flap

Contact person

Mr. Käuser

phone: +49 2734 509-34

email: fat.info@f-a-t.de

Rolling lumps breaker

FAT-specific component

Rolling lumps breakers are used for crushing boiler fly ash. These machines are available in single-shaft or double-shaft design.

Your contact for rolling lumps breakers

Contact person

Mr. Käuser

phone: +49 2734 509-34

email: fat.info@f-a-t.de

Impact crusher

Grinding of agglomerates in bulk material

The impact crusher is mainly used for ash crushing after combustion process so that it can be pneumatically conveyed in an operationally save manner.

Your advantages

Easy to maintain

Key transfer system for high security

Bypass function

Drawer for non-crushable foreign matter

Your contact for impact crushers

Contact person

Mr. Käuser

phone: +49 2734 509-34

email: thomas.kaeuser@f-a-t.de

Your direct

contact to us

You want to convey mechanically?

Are you looking for a partner for your individual application?

Get in touch with us: